Working the Next Sculpture

These two pieces will be bronze with a black patina – wall mounts as a backdrop for an outdoor courtyard fountain. The smaller of the two pieces is 4′ x 6′, the larger piece is 13′ x 6′. I decided to do this in bronze because it will weather better than granite or basalt and frankly, it should be quicker to do it given the changes in technology.

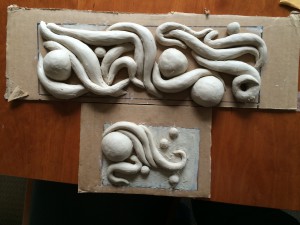

The process is similar to what it has been in the past when I did other bronze pieces. First, I created clay moquettes for the two pieces 1/12th scale to the final pieces:

We scanned the pieces in a 3D CAD program:

We scanned the pieces in a 3D CAD program:

We translated the CAD file into a full scale replica cut into dense blue foam media, using a 5 axis CNC machine and then work the rough foam into something that refines the 3D model :

We translated the CAD file into a full scale replica cut into dense blue foam media, using a 5 axis CNC machine and then work the rough foam into something that refines the 3D model :

The next step is to work the surface textures, create casts and models in wax, take it to the foundry for the bronze infusion via the lost wax method, weld the silicon bronze pieces, chase the bronze and then patina.

Hard work, but ultimately less stressful on my arms and back then the pneumatic chiseling, grinding and polishing necessitated by working with basalt. More to come on this as we progress on the sculptures. Am very lucky to be working with a great foundry run by fellow sculptors at the Classic Art Foundry in Seattle.